THE FIN 🦈 REVIEW

Cut through the noise (and the air) with MicroTau’s monthly newsletter, The Fin🦈Review.

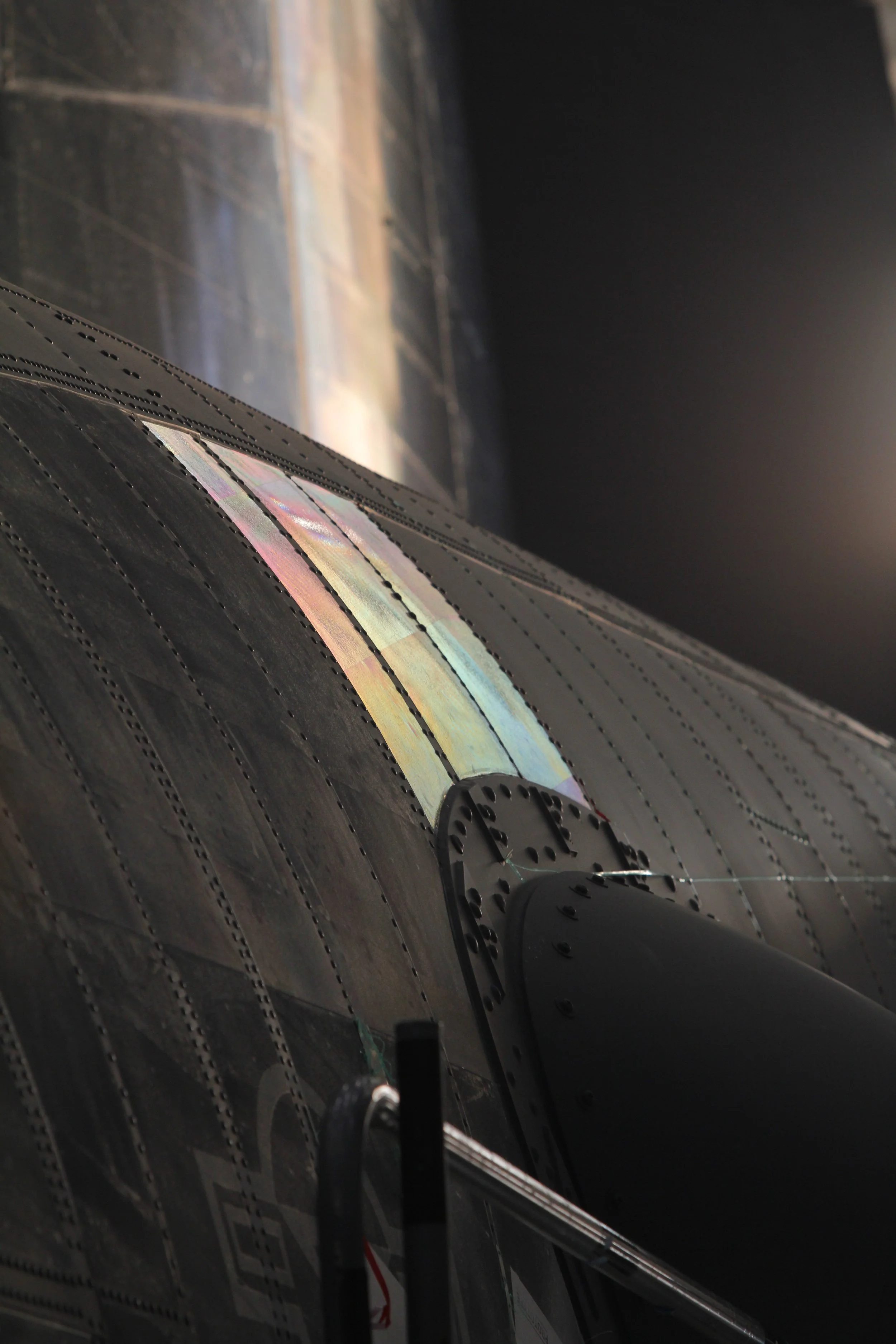

Each month we’ll demystify and simplify the world of sharkskin-inspired drag reduction products and demonstrate their applications in commercial and defence aviation. No need to circle the waters - we'll bring you straight to the good stuff:

📣 WHAT WE’RE UP TO: Be among the first to hear about the latest product development news and company announcements from MicroTau

😎 HOW IT’S DONE: Behind-the-scenes product development insights and explainers

🚀 WHY WE DO IT: Aviation, climate, and defense industry news and trends analysis

📆 WHERE WE’LL BE: Where to meet us at industry events

👩🔬 WHO WE ARE: Meet the sharp minds engineering the future of aviation and how you can join the fleet